Self-tapping screws

Thread-forming screw – ST thread

Thread-forming screw – ST thread

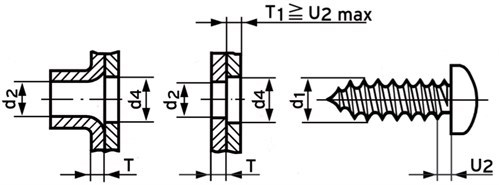

Hole recommendation for plate screw

|

Thread |

Plate thickness |

Hole diameter d2 H12 or H13 1) |

Clearance hole |

|||||||||

|

Steel, brass, copper2) |

Aluminium |

Cast metal alloy of zinc, magnesium, aluminium and brass |

Plastic |

|||||||||

|

Punched or knocked out holes |

Drilled or cut holes |

Punched or knocked out holes |

Drilled or cut holes |

Thermosetting plastic |

Thermoplastic |

|||||||

|

Hole group 1A |

Hole group 1B |

Hole group 2A |

Hole group 2B |

Hole group 3 |

Hole group 4 |

Hole group 5 |

||||||

|

d2 |

3) |

d2 |

3) |

d2 |

3) |

|||||||

|

ST 2.2 |

- 0.56 |

- |

1.6 |

- |

- |

2 |

3 |

2 |

5 |

2 |

5 |

2.8 |

|

ST 2.9 |

- 0.56 |

2.2 |

2.2 |

- |

- |

2.7 |

5 |

2.5 |

6.5 |

2.4 |

6.5 |

3.6 |

|

ST 3.5 |

- 0.56 |

2.8 |

2.6 |

- |

- |

3.3 |

6.5 |

3.2 |

6.5 |

3 |

6.5 |

4.2 |

|

ST 4.2 |

- 0.5 |

3.5 |

- |

- |

- |

3.9 |

6.5 |

3.8 |

8 |

3.7 |

8 |

5 |

|

ST 4.8 |

- 0.5 |

4 |

- |

- |

- |

4.5 |

6.4 |

4.5 |

8 |

4.3 |

8 |

5.8 |

|

ST 5.5 |

- 1.13 |

4.7 |

4.2 |

- |

- |

5 |

7 |

5 |

9.5 |

4.8 |

9.5 |

6.6 |

|

ST 6.3 |

- 1.38 |

5.3 |

4.9 |

- |

- |

5.9 |

8 |

5.9 |

9.5 |

5.6 |

8 |

7.4 |

1) If H13 is selected, the specified values for d2 must be reduced by 0.1 mm.

2) HB max. 120. In the case of harder materials, the table values are increased by 0.1-0.2 mm.

3) Min. screw-in length. The values in the table apply to case-hardened screws made of steel.For ST threaded screws made of another material, e.g. stainless steel or brass, installation tests should be performed in each individual case.